FOCUS has manufactured and continuously developed the EFM range of evaporators since 1990, gaining a global reputation on being the preferred provider of sources for all research systems.

These UHV e-beam evaporators are dedicated to ultra-pure sub-monolayer to multilayer thin film growth under ultra high vacuum (UHV) conditions.

Hereby, evaporant material ranges from metals to individual molecules.

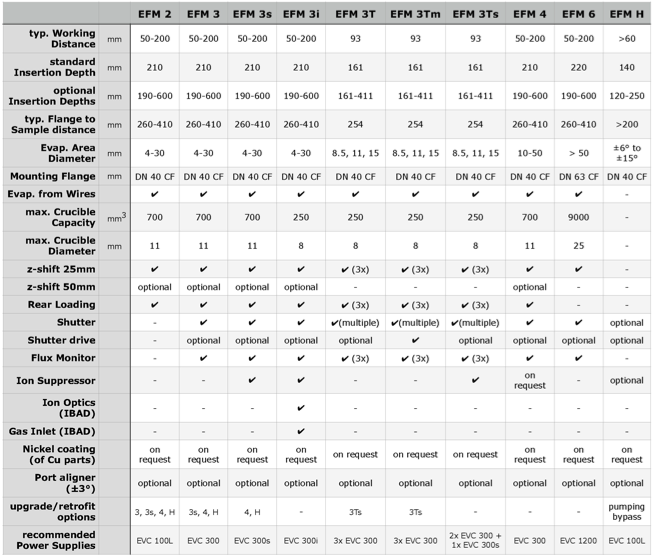

There is a growing family from the simplest EFM3 to much more sophisticated special solutions like the EFM3i. For a quick survey please have a look here.

For an overview of our EFM Series please check out our in-depth brochure!

- Evaporation from wires, rods or crucibles

- Temperature range up to 3300 °C

- Integrated flux monitor

- Water cooling for minimum pressure rise

- Rear loading for alignment preservation

- Comfortable lab view-based PC software

- Most popular UHV evaporator worldwide

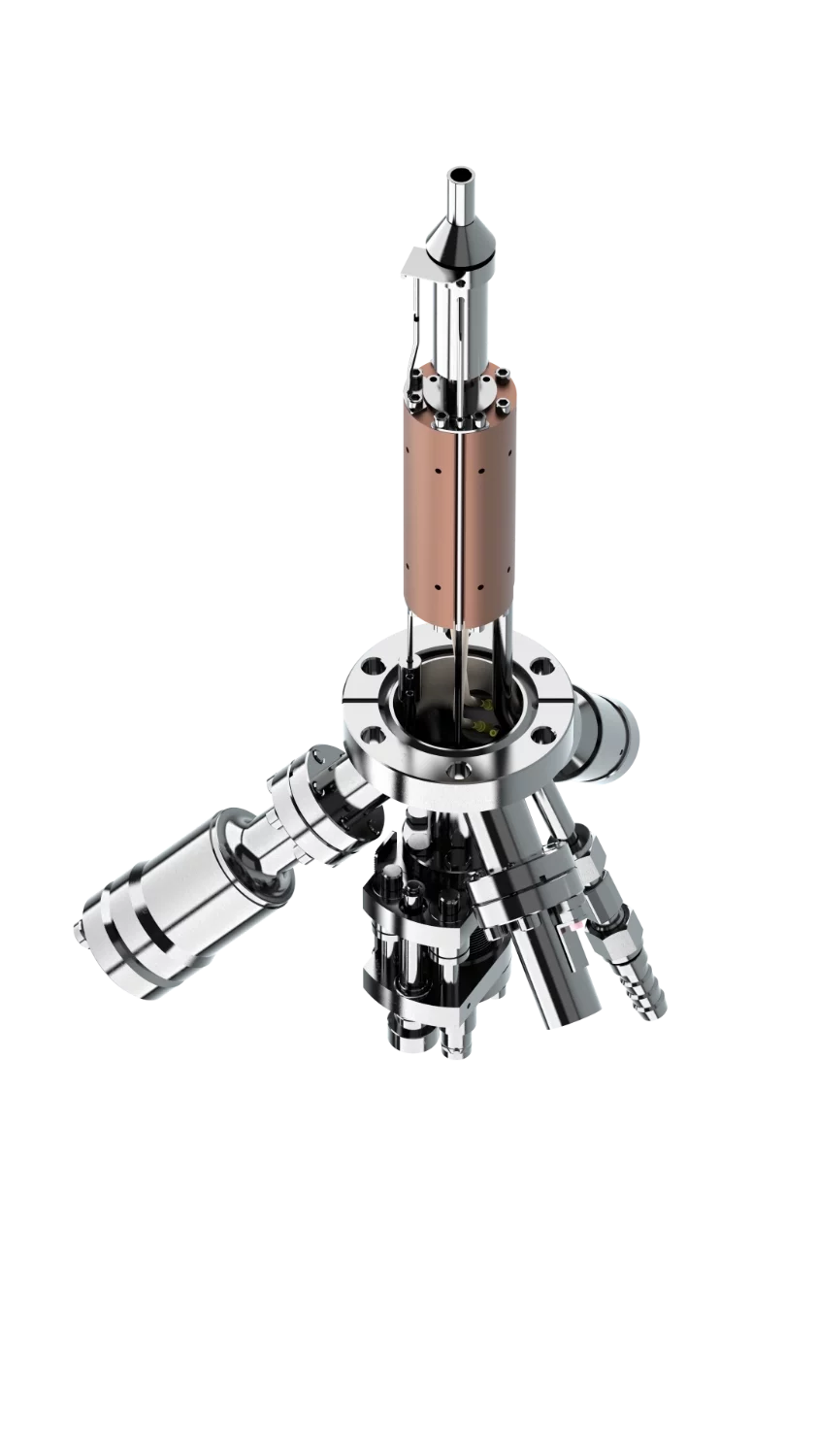

EFM 3

The classic

The EFM 3 with its proprietary cooling concept has been the first commercial evaporator using an integrated flux monitor. The design has been so successful that it sets the reference for ultimate clean evaporation in UHV.

EFM 3s

Suppressing ions

Adds ion suppression to the classic EFM3 to prevent high energetic ions generating defects at the surface.

Requires the corresponding power supply.

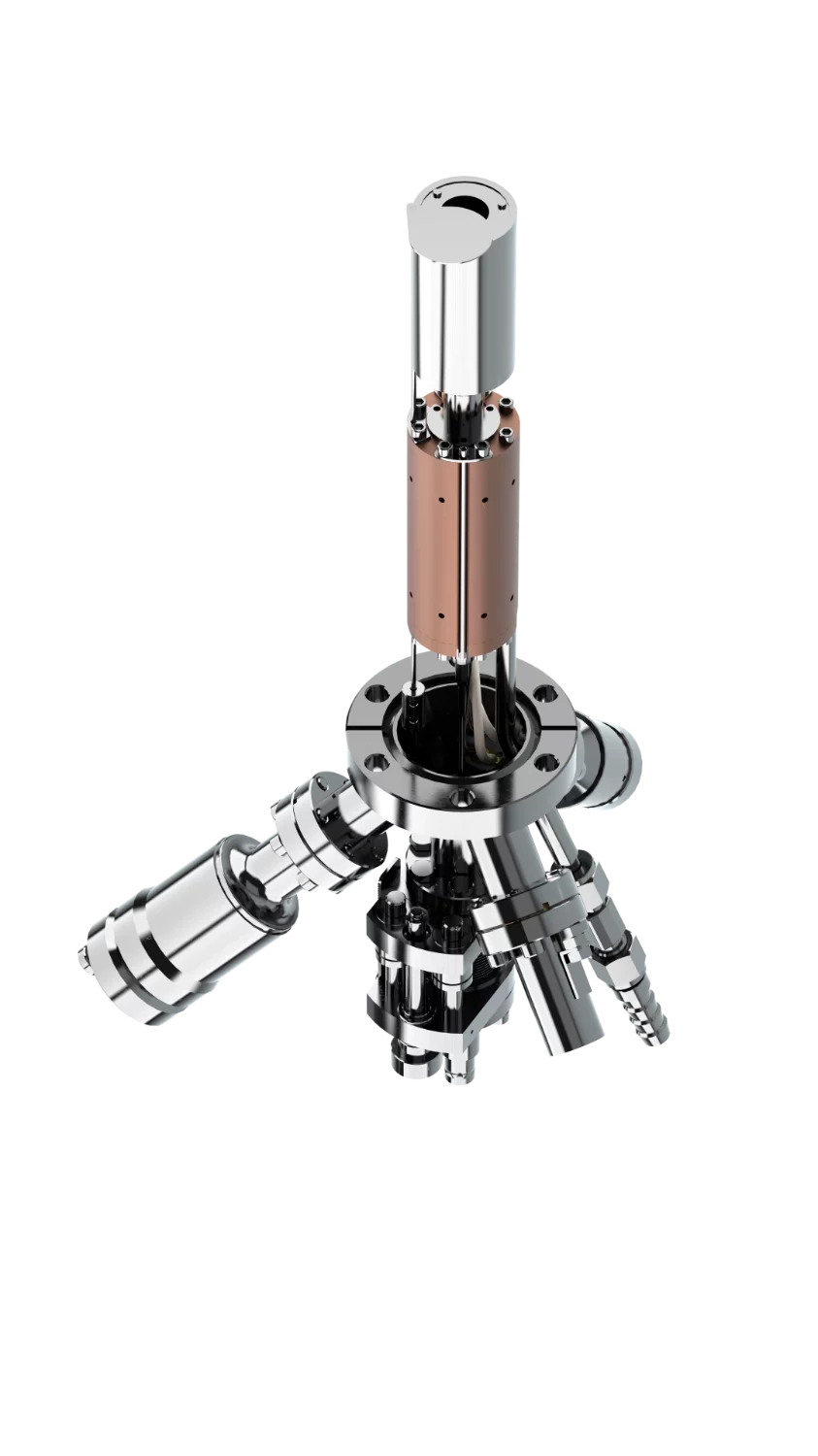

EFM 3i

Ion-Beam-Assisted Deposition (IBAD)

The EFM3i is designed to controllably induce additional defects at the surface, to facilitate layer-by-layer growth where it does not occur naturally.

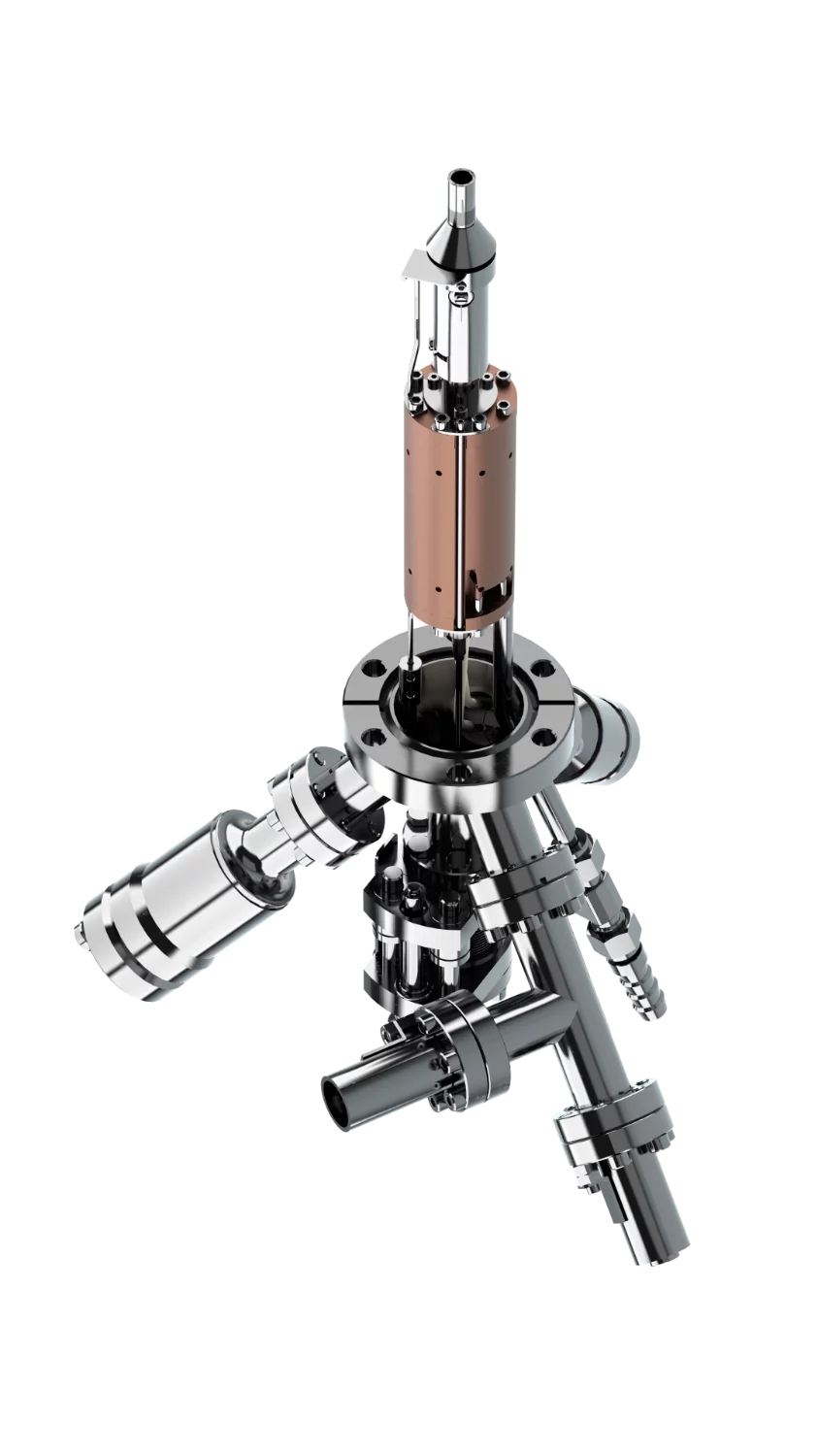

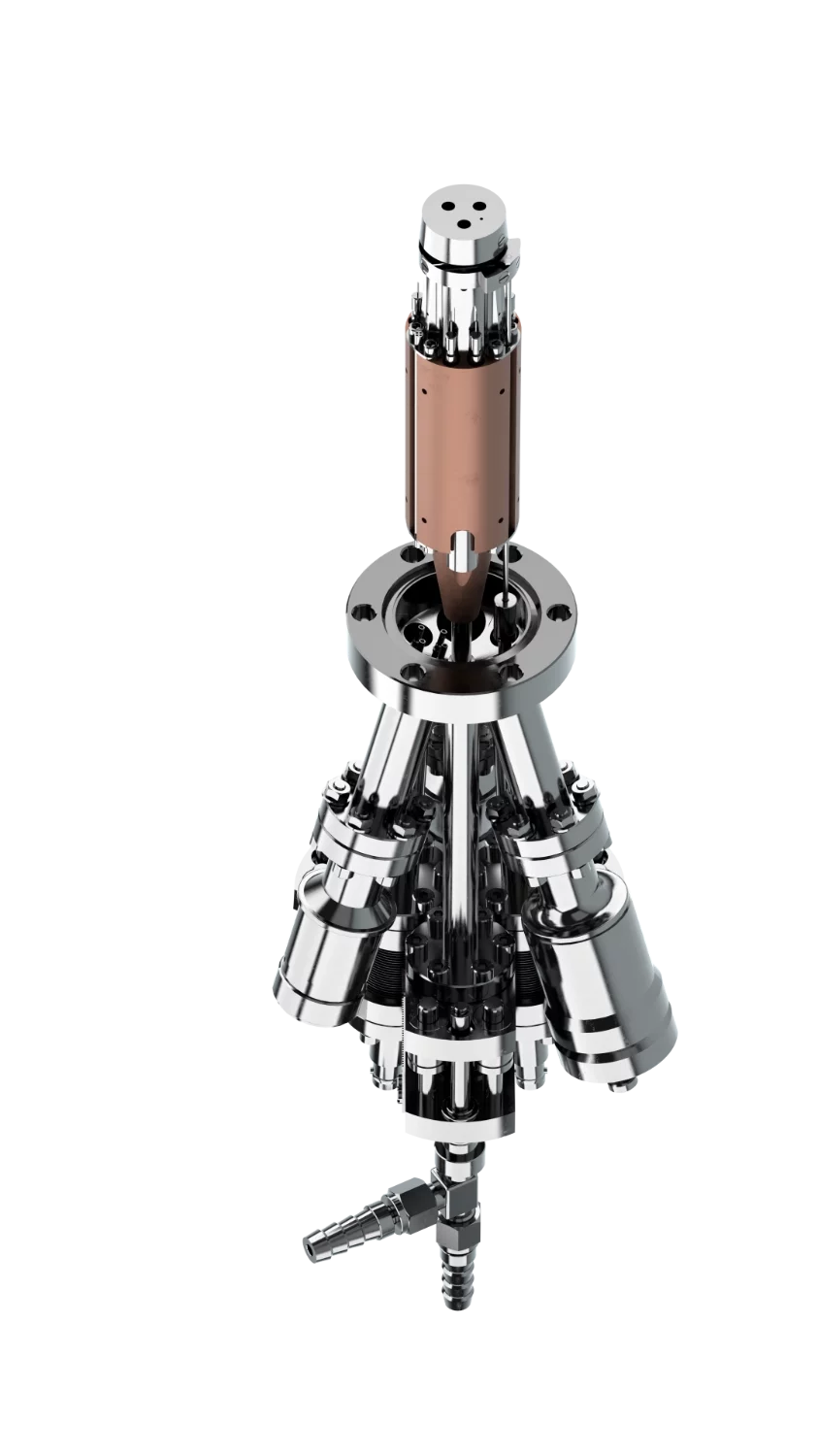

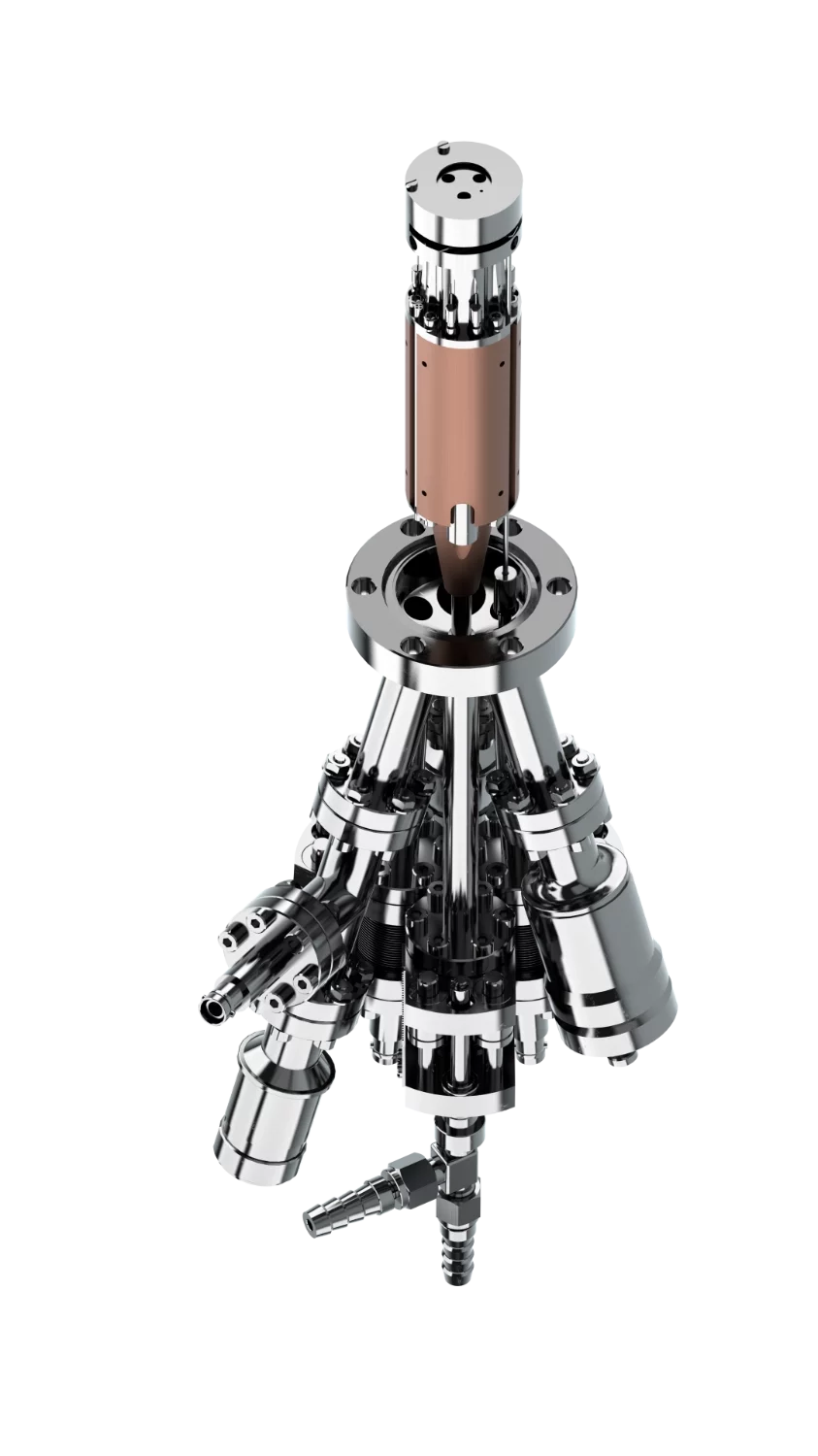

EFM 3T

Three sources at once

Mounted on a DN40 (2 ¾”) flange, the EFM 3T offers the option of sequential or co-deposition of up to 3 materials. The benefits of the classic single source are maintained including linear rod retraction and independent flux monitoring.

EFM 3Ts

Three sources on one flange with Ion suppression

All the benefits of a triple evaporator, with the benefits of our ion suppression.

Adds ion suppression to the EFM 3T to prevent high energetic ions generating defects at the surface.

EFM 4

For large Samples

The EFM 4 provides the same features as the EFM 3 but is intended for the deposition on substrates with a larger diameter up to about 50 mm.

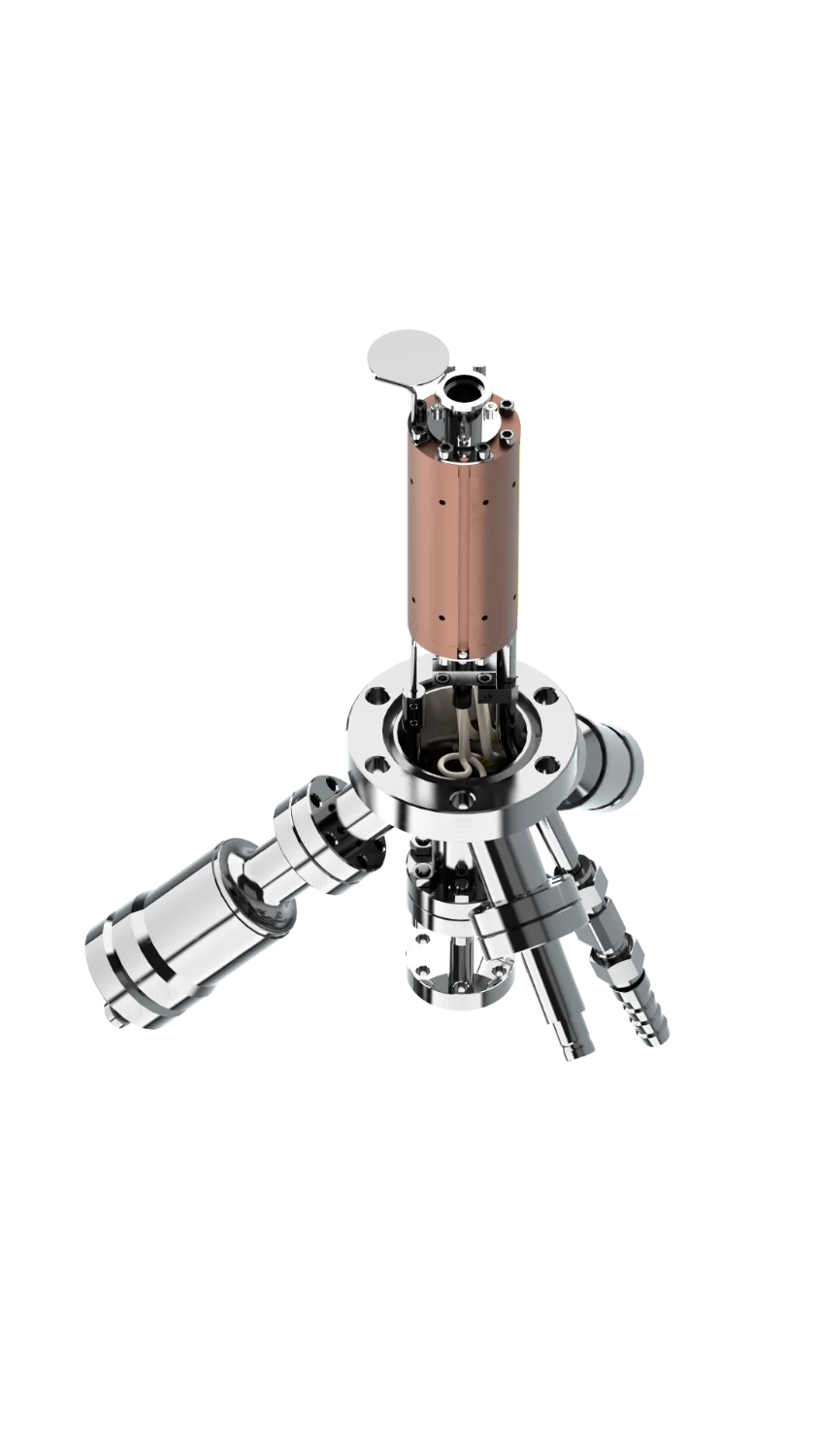

EFM-H

Atomic Hydrogen Source

The EFM-H is an ideal instrument for the cleaning and etching of semiconductor surfaces (such as Si, GaAs, Ge or InP), for surface passivation, for improvement of thin film growth and other similar applications using atomic hydrogen.

Electronics & Software

The microprocessor controlled EVC power supplies enable the EFM-series to address a temperature range from 100°C – 3300°. The EVC comes with the LabVIEW™*-based Epitass® software. As a unique feature Epitass® software has a temperature display providing the actual crucible temperature.

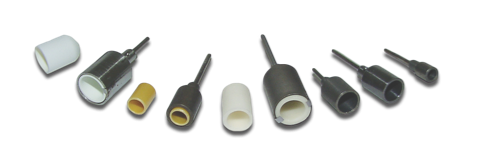

Spare Parts & Services

For the EFM-series as consumables we offer a large range of different crucibles and barrel connectors. Most of the components of the evaporators are available as individual items and ensure sustainable serviceability since 1991.