EFM H: Atomic Hydrogen Source

Features at a glance:

- Effective water cooling

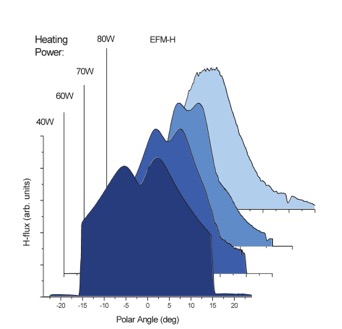

- FWHM: ± 15° to ± 6° (approx.)

- Flange to sample distance: 203 mm or larger

- Insertion depth: 141.5 mm

- Compatible with EVC Series Controllers

- Options: shutter, pumping bypass and ion suppressor (neutral beam)

- Mounting flange NW 35 CF

For a quick check of all technical features please refer to the survey table and for the major dimensions to the technical reference drawing in our brochure .

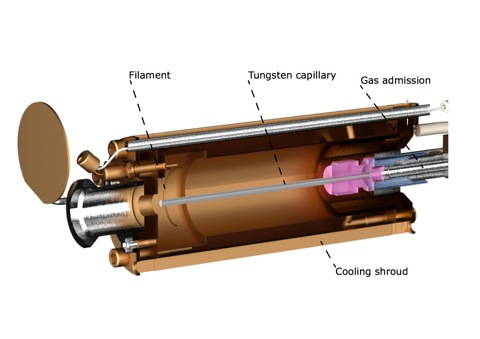

The EFM-H is a source to provide atomic hydrogen based on the design of the EFM 3. A flange NW 16 CF on the rear side is used for molecular hydrogen inlet including a pumping by-pass to clean the piping prior to H2 disposal.

The EFM-H is an ideal instrument for the cleaning and etching of semiconductor surfaces (such as Si, GaAs, Ge or InP), for surface passivation, for improvement of thin film growth and other similar applications using atomic hydrogen.

The EFM-H features a cracking efficiency close to 100%, a smooth, flat and sharply defined spot profile, a low background pressure and a surprisingly low power consumption, demonstrating the outstanding performance of the EFM-H.

The temperatures, heating power, and other parameters required for the thermal dissociation of H2 molecules at a tungsten surface are very similar to those applied during operation of the well-known EFM evaporator. The crucible is replaced by a thin tungsten capillary through which Hydrogen is introduced. The tungsten capillary is then heated by electron beam bombardment.

The typical kinetic energy of the Hydrogen atoms produced is about 250 meV. Since the heated area is efficiently shielded by the EFM’s distinctive copper cooling shroud, the level of outgassing is negligible.

The geometry of the EFM-H enables excellent alignment of the hydrogen beam onto the sample, allowing for example an atomic hydrogen flux of 2×1015cm-2s-1 at a chamber background pressure of 2×10-6 mbar (mainly recombined hydrogen molecules).

Depending on the heating power (i.e. the temperature and length of the heated Tungsten area), the spot profile can be varied. Either a focused beam for small samples, or a wider beam for larger samples may be selected.

Please refer to the electronics page.

For more information see the related brochure.