Main features:

- Highly reproducible closed loop flux regulation with adjustable parameters

- Regulated emission current

- Programmable automatic thin film deposition (as a function of exposure or time)

- Easy adjustment of operating parameters via user friendly menu structure

- Deposition parameters can be stored and recalled for repeated procedures

- Automatic growth based on control of the shutter position or the heating power

- Up to 300W e-beam power

- All existing EFM evaporators delivered after 1990 can be operated with all of our latest power supplies because of a full pin compatibility!

The microprocessor controlled EVC power supplies make the operation of all EFM-type UHV evaporators very convenient and safe.

With up to 300 W power output they are sufficient for the evaporation of any desired material.

Automatic temperature monitoring of the evaporator cooling ensures automatic shutdown if a pre-selectable maximum temperature of the cooling shroud is exceeded. An external interlock is provided for the vacuum integrity.

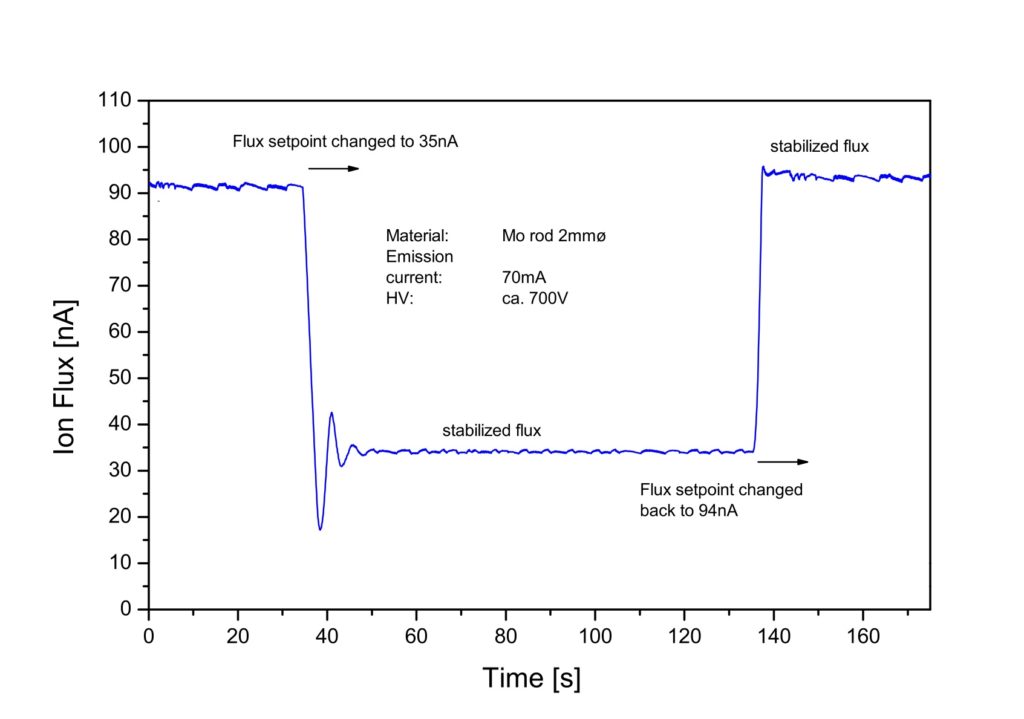

The EVC 100 & 300 power supplies come with full flux regulator in addition to the emission current regulator which can be programmed for constant flux or integral flux values. The EVC 300 flux monitoring system provides precise control of the evaporant flux. The regulation parameters can be adjusted to ensure excellent response even with rapid changes of the flux setting as demonstrated here.

All parameters of the EVC power supplies including those for the optional motorized shutter can be set manually on the front panel or via the Lab VIEW™*-based Epitass® software.

The software logbook of Epitass® ensures a full documentation of the experiment and allows to re-load complete sets of parameters.

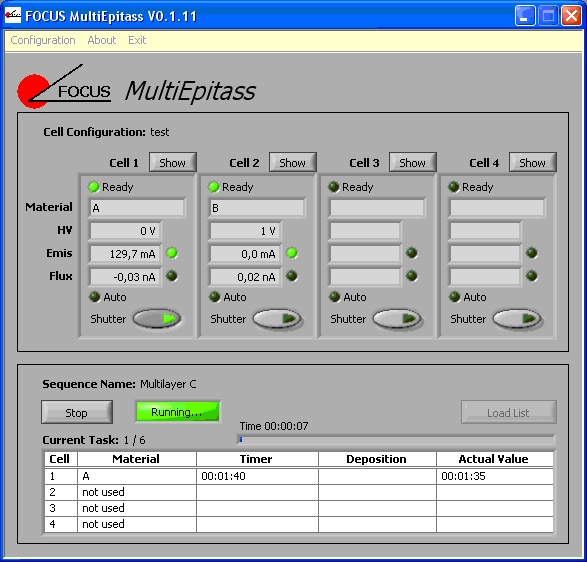

For Multilayer growth or co-evaporation from different cells several EVC power supplies need to be controlled. This functionality is provided by the MultiEpitass® software which can control up to four different cells mastering the individual Epitass® software of each EVC power supply. The MultiEpitass® is an option or part of an EFM 3T-EVC 300 package.

All evaporators including the EFM-H can be equipped with a motorized shutter which is either mounted at the factory or can easily be refitted by the customer. The shutter electronics is integrated in all power supplies EVC 300/ 300s/300i. The shutter software control is an integral part of Epitass® and MultiEpitass® .The shutter motor is an ideal support for multi-layer growth and co-evaporation.

EVC 100L

In contrast to the EVC 100(s)/300 (s) /1200, the EVC 100L is a simple analogue unit without flux monitor. High voltage, filament current and emission current are monitored on two displays and adjusted via potentiometers. For stable evaporation properties the emission current is regulated; an important feature and not common in this segment of the market. It has no interface and can not be remote controlled by Epitass®.

To find out the right power supply for the chosen evaporator please refer to the survey table.

For more information see the related brochure.