Hot Filament Ion Source

- Differential pumping

- Non line-of-sight filament

- Integrated port aligner

- 30 – 300 mm working distance

- Variable spot size

- Down to 10 eV kinetic energy (optional)

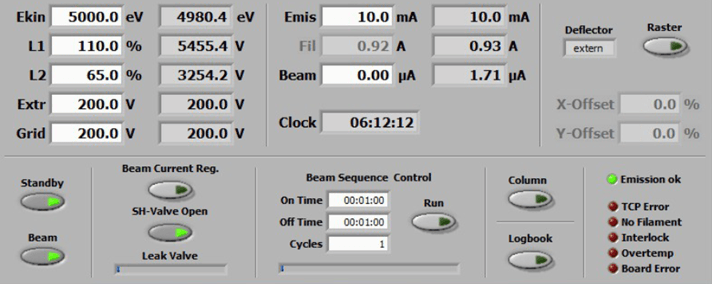

- Flux regulation included

The FDG range of hot filament ion sources, is the premium product line when you need to: clean metals and semiconductors1)-4) or undertake XPS Depth Profiling, ISS/LEIS experiments or as a < 15 eV Charge Neutralization source. All variants operate as standard with Argon gas but other noble gases or reactive gases like Hydrogen or Oxygen are also fully compatible. Both ion sources are made of completely non-magnetic materials and are compatible with high-resolution electron spectroscopy. An ultra clean ion beam is ensured by an indirect filament, a direct gas inlet for minimizing dead volume and effective differential pumping. The power supply can be fully controlled with the front panel or via a TCP/IP interface. ProIon, an easy to use LabVIEWTM – based PC software is provided.

Technical Details

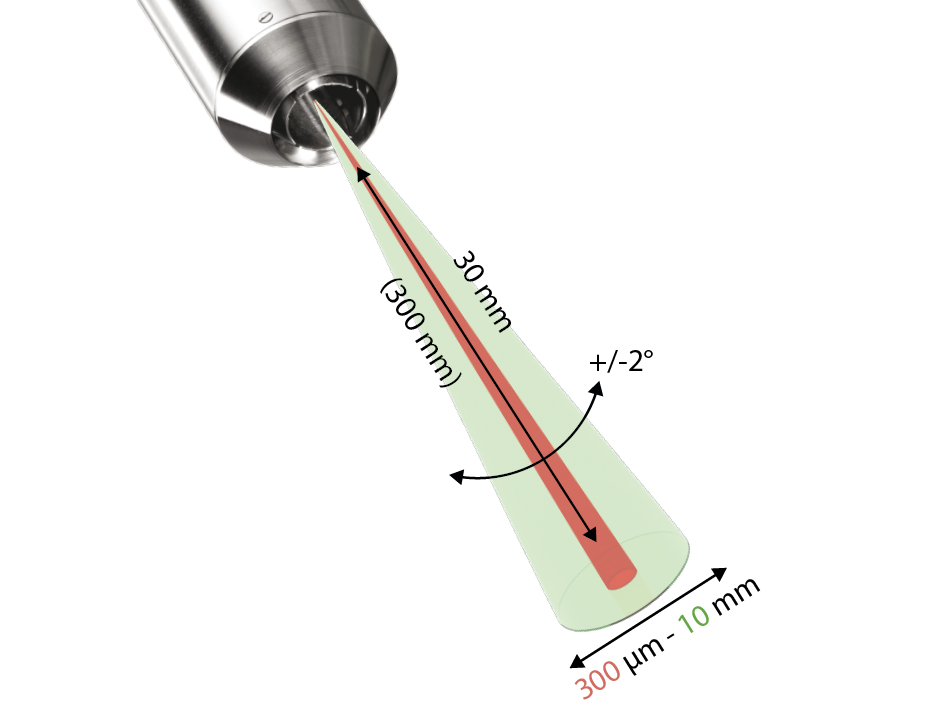

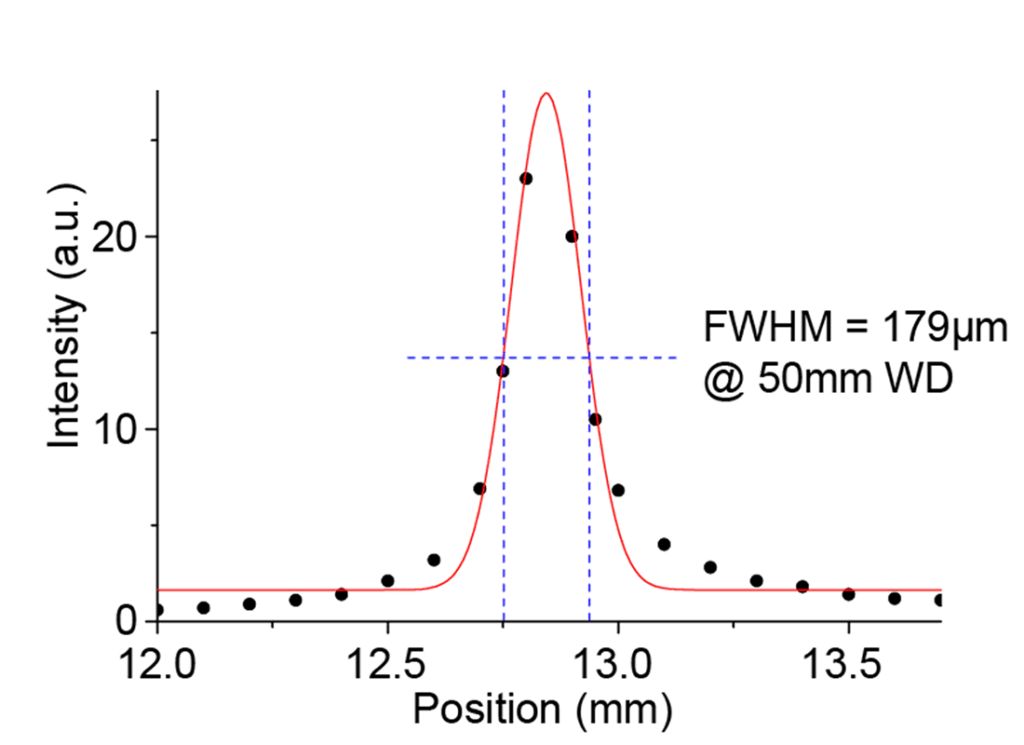

The dedicated ion optics allows focusing the spot size down to 300 µm @ 50 mm working distance for sputtering of small crystals and to adapt for large working distances up to 300 mm.

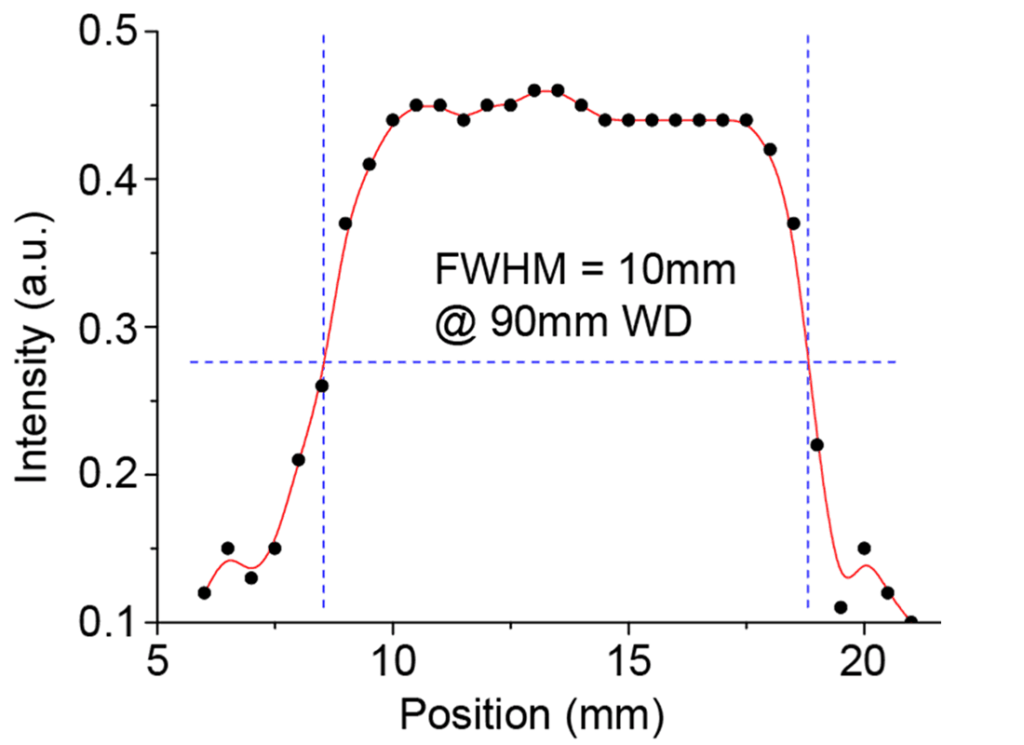

Alternatively a broad spot profile can be chosen for homogeneous large area sputtering.

In addition, the source comes with a high stability emission current based flux regulation.

The source can be operated with or without differential pumping. The latter provides improved residual gas pressure of typ. 10-8 mbar.

The optional low energy mode provides a comparable large ion current of > 1 µA @ 50 eV.

Ion sputtering at low energies (< 100eV) of semiconductors close to the threshold energy is critical to minimise ion implantation and surface damage1)-4).

Lower energy ion sputtering, at 50 eV, even maintains the sample magnetisation during XPS depth profiling5).

Spot Size & Beam Positioning Range

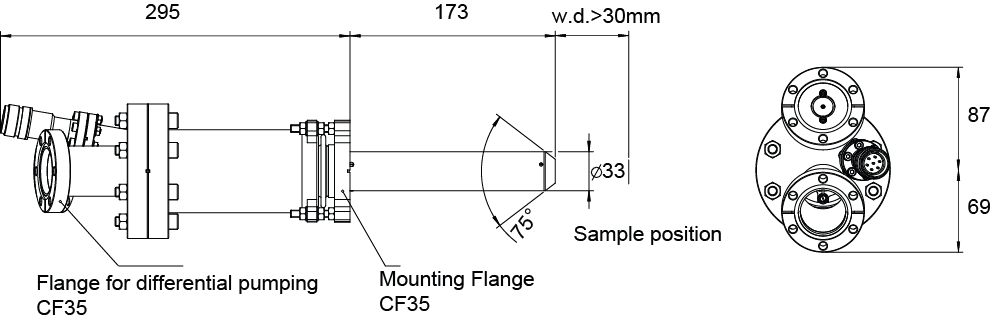

Technical Drawing

Technical Specifications

The table shows the FDG 15 specifications in comparison to the FDG 150:

| Features | FDG 15 & power supply | FDG 150 & power supply |

|---|---|---|

| Mounting flange | DN 40 CF | DN 40 CF |

| Working Distance (WD) | 30 to 300 mm | 30 to 300 mm |

| Min. beam diameter (D) | < 300 μm (@ 5 keV and 50 mm WD) | < 150 μm (@ 5 keV and 50 mm WD) |

| Beam energy 1 | 500 eV to 5 keV> 15 μA (@ 5 keV and 50 mm WD) | 500 eV to 5 keV> 15 μA (@ 5 keV and 50 mm WD) |

| Beam energy 2 | optional | 10 eV to 500 eV; > 1 µA @ 50 eV |

| Beam current density | > 4 mA/cm2 with > 5 µA, D < 350 µm (@ 5 keV and 50 mm WD) | > 4 mA/cm2 with > 5 µA, D < 200 µm (@ 5 keV and 50 mm WD) |

| Scan area | not available | up to 10 mm x 10 mm (@ 5 keV and 50 mm WD) |

| Beam current regulation | ✓ | ✓ |

| Integrated Port Aligner | ✓ | ✓ |

| Current measurement | ✓ | ✓ |

| TCP/IP Interface | ✓ | ✓ |

| LabVIEW based software | ✓ | ✓ |

| Fully non-magnetic | ✓ | ✓ |

| Yttria coated tungsten filament (compatible with O2) | ✓ | ✓ |

| Tungsten filament (compatible with H2) | optional | optional |

| Leak Valve | optional | optional |

1) Chebotarev, S. N. et al. “Low-Energy Ion Technique for Semiconductor Surface Preparation.”

Solid State Phenomena, doi:10.4028/www.scientific.net/ssp.284.198;

2) Dongwan Seo et. al. „Behavior of GaSb (100) and InSb (100) surfaces in the presence of H2O2 in acidic and basic cleaning solutions”, doi.org/10.1016/j.apsusc.2016.12.114

3) Shiou-Min Wu et al. “Sputtering yields of Ru, Mo, and Si under low energy Ar+ bombardment”, Journal of Applied Physics 106, 054902 (2009); doi: 10.1063/1.3149777

4) Hye Chung Shin et al. “Sputter damage in Si surface by low energy Ar+ ion bombardment”, Current Applied Physics 3 (2003) 61–64

5) B. J. McMorran et al., Measuring the effects of low energy ion milling on the magnetization of Co/ Pd multilayers using scanning electron microscopy with polarization analysis. Appl. Phys. 107, 09D305 (2010);

https://doi.org/10.1063/1.3358218