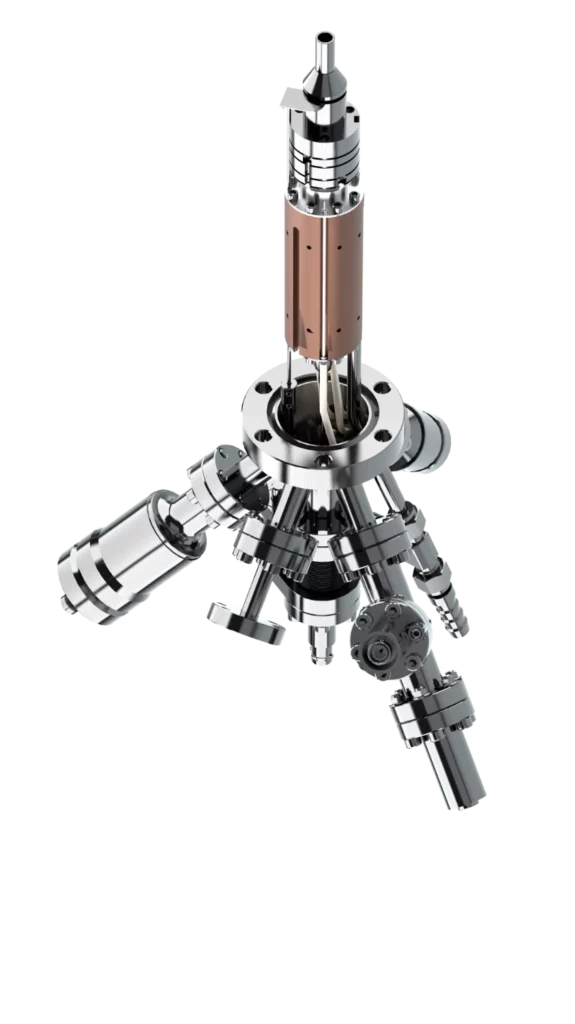

EFM 3i: Ion-Beam-Assisted Deposition (IBAD)

Features at a glance:

- Evaporation area 4 – 30 mm

- Flux monitor

- Integrated shutter

- Gas inlet for additional gas

- Ion focusing lens for Ion-Beam-Assisted Deposition (IBAD)

- Ion suppression

- Crucible capacity up to about 300 mm3

- Mounting flange NW 35 CF

- All other features same as EFM 3

360° 3D-view:

For a quick check of all technical features please refer to the survey table and for the major dimensions to the technical reference drawing in our brochure .

The EFM 3i is specifically designed to facilitate layer-by-layer growth in cases where it does not occur naturally. Please refer to the application page.

It allows for the controlled evaporation of the target material, and the simultaneous generation of ions to create additional surface defects (Ion-Beam-Assisted Deposition, IBAD).

The ions can be produced either by an intrinsic process from the evaporated target material, or from inert gases with the help of an integrated gas inlet. The ions are focused onto the substrate by an electro-static lens. This focusing lens can adjust the ratio of ions to neutrals within the deposition area at the target and hence inducing the additionally defect density.

Alternatively sensitive substrate materials can be protected against ion bombardment by a repelling lens voltage (see EFM3s).

The dedicated EVC 300i power supply supports not only the evaporation process but also supplies the additional lens voltage and includes a sample current meter. Please refer to the electronics page.

Due to the special design of the ionization region the max. crucible size is limited.

See also: J.Kirschner, H. Engelhard, and D. Hartung, Rev. Sci. Instrum., Vol. 73, No. 11, p. 3853-3860, 2002.

For more information see the related brochure.